High-performance hydrogen storage technology at room temperature

Domains

Environenment

Energy

Mobility

Technologies

Advanced and active materials

Hydrogen technologies

CHALLENGES

Hydrogen is anticipated to be one of the fuels of the future for mobility. However, its value chain remains to be constructed. Solid-state storage is the major issue. The currently available technologies still present drawbacks: too high energy cost in use, uncontrolled charge-discharge cycles, and sometimes polluting materials.

INNOVATIVE SOLUTION

This innovation is a porous composite, easy to implement, with relevant properties for hydrogen storage at room temperature and atmospheric pressure.

Applications

- Heavy mobility

- Chemical industry

- Stationary storage

Advantages

Easy to implement

- Stable H2 storage under standard pressure and temperature conditions (1 bar, 25°C)

- Reversible storage

- Possible release at low temperature < 100°C

- Cost-competitive manufacturing

- Hydride-free

DEVELOPMENT STATUS : TRL 3

What has already been done:

- POC

- Laboratory tests

Next steps:

- Optimizations according to the specifications defined with the co-developer (operating conditions, cycles, choice of materials, etc,)

- Industrialization of the process

HOW IT WORKS

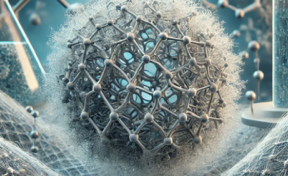

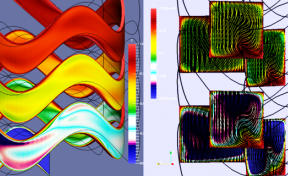

Manufacturing process of the porous composite:

The process involves impregnating organics into a porous matrix, without the use of solvents, to enable the charging, storage, and discharge of hydrogen.

The porous matrix:

- Microporous and/or mesoporous supports

- Pore diameter < 10 nm, representing > 30% of the volume

- Specific surface area: between 200 m²/g and 3000 m²/g

The organic compound:

- Forms hydrogen bonds

- Preferably hydroquinone or urea

- Occupies at least 25% of the porous volume of the matrix

Charge-discharge process :

The porous composite allows for hydrogen charging by lowering the temperature (1). Discharge is possible by returning to room temperature (2). Once discharged, the composite material can once again receive and store hydrogen.

Inventors

Developed by C.MIQUEU, A. PENNETIER, L.PERRIER, J.P. TORRE - Laboratory of Complex Fluids and Their Réservoirs (LFCR)

IP

Patent filed in 2022

PARTERSHIPS

The SATT Aquitaine and the researchers behind the project are seeking for an industrial partner willing to engage in a co-development process to push the technology to a higher TRL

Contact

Marlène OLIVEIRA SANTOS

%6d%2e%6f%6c%69%76%65%69%72%61%73%61%6e%74%6f%73%40%61%73%74%2d%69%6e%6e%6f%76%61%74%69%6f%6e%73%2e%63%6f%6d

+33 (0)6 63 37 41 38