BaTiO3 nanosheets for the formulation of dielectric inks with remarkable properties meeting the technical requirements of printed electronics

Domains

Energy

Digital

Technologies

Internet of Things

Nanoelectronics

CHALLENGES

With the development of printed electronic devices, the performance of dielectric inks is constantly challenged. These inks are used to create insulating layers between conductive elements, enabling the printing of complex circuits, sensors and dielectric capacitors in a wide range of applications, including flexible transistors, radio frequency identification (RFID) antennas ), touch screens and solar systems.

Dielectric inks on the current market lack electrical and chemical stability, are not compatible with all substrates or all printing techniques.

INNOVATIVE SOLUTION

The innovation of this formula lies in its 2D morphology obtained by gentle chemistry with a yield of 100% and a high surface/thickness ratio. This morphology gives the formula interesting insulating properties, such as a high breakdown voltage.

Applications

-

Insulation in printed electronics (automotive, medical devices, aerospace and defense)

-

Internet of Things

-

energy storage

Avantages

-

High dielectric constant

-

Soft chemistry formulation

-

Compatible with various printing techniques

-

High resolution and optimized flexibility

DÉVELOPPEMENT : TRL 2

-

Improvement in the crystallinity rate of nanosheets

-

Increase in permittivity

-

Nanosheet formulations dispersed in non-aqueous solvents used in industry

HOW IT WORKS

Synthesis of BaTiO3 nanosheets:

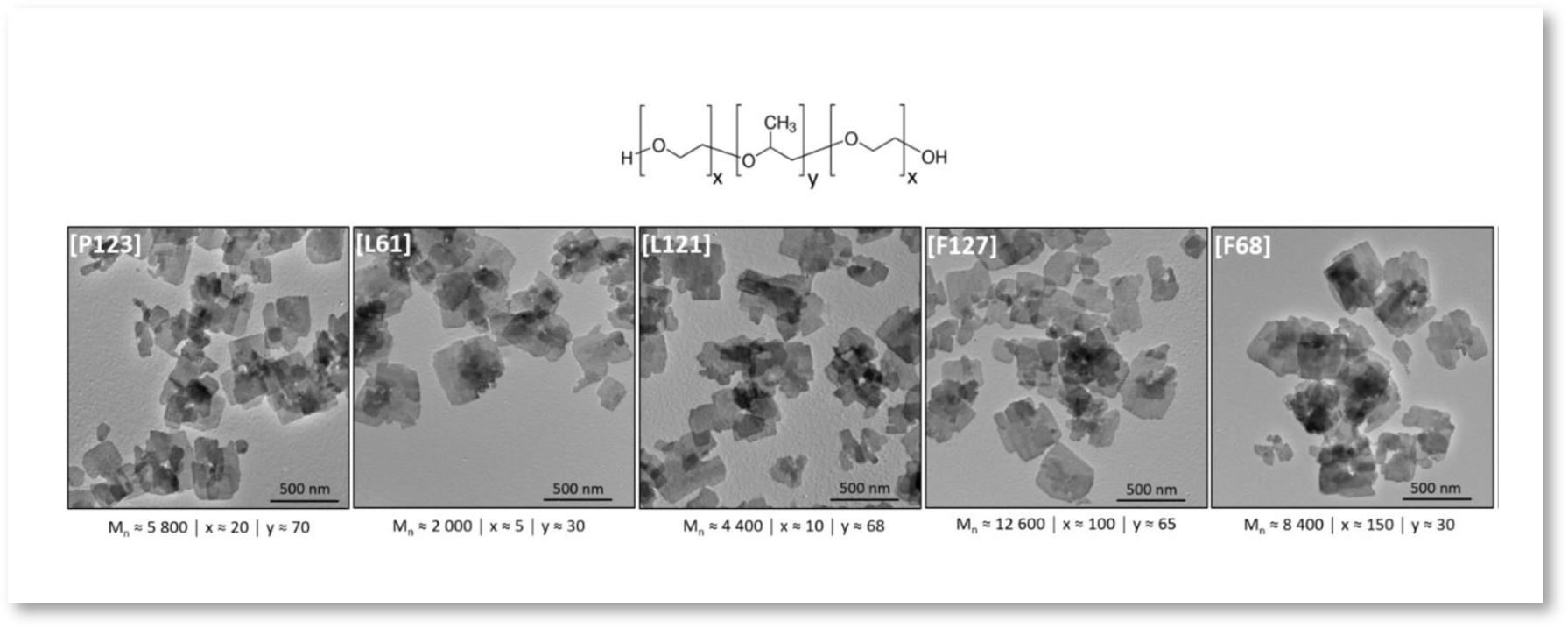

A TiO2 precursor is first synthesized in the form of 2D nanosheets under optimized solvothermal conditions. Mixed with an aqueous solution of Ba(OH)2 during a hydrothermal reaction, BaTiO3 nanosheets are then produced. Controlling the size and shape of these sheets is possible, and directly linked to the quantities of reagents.

Ink formulation:

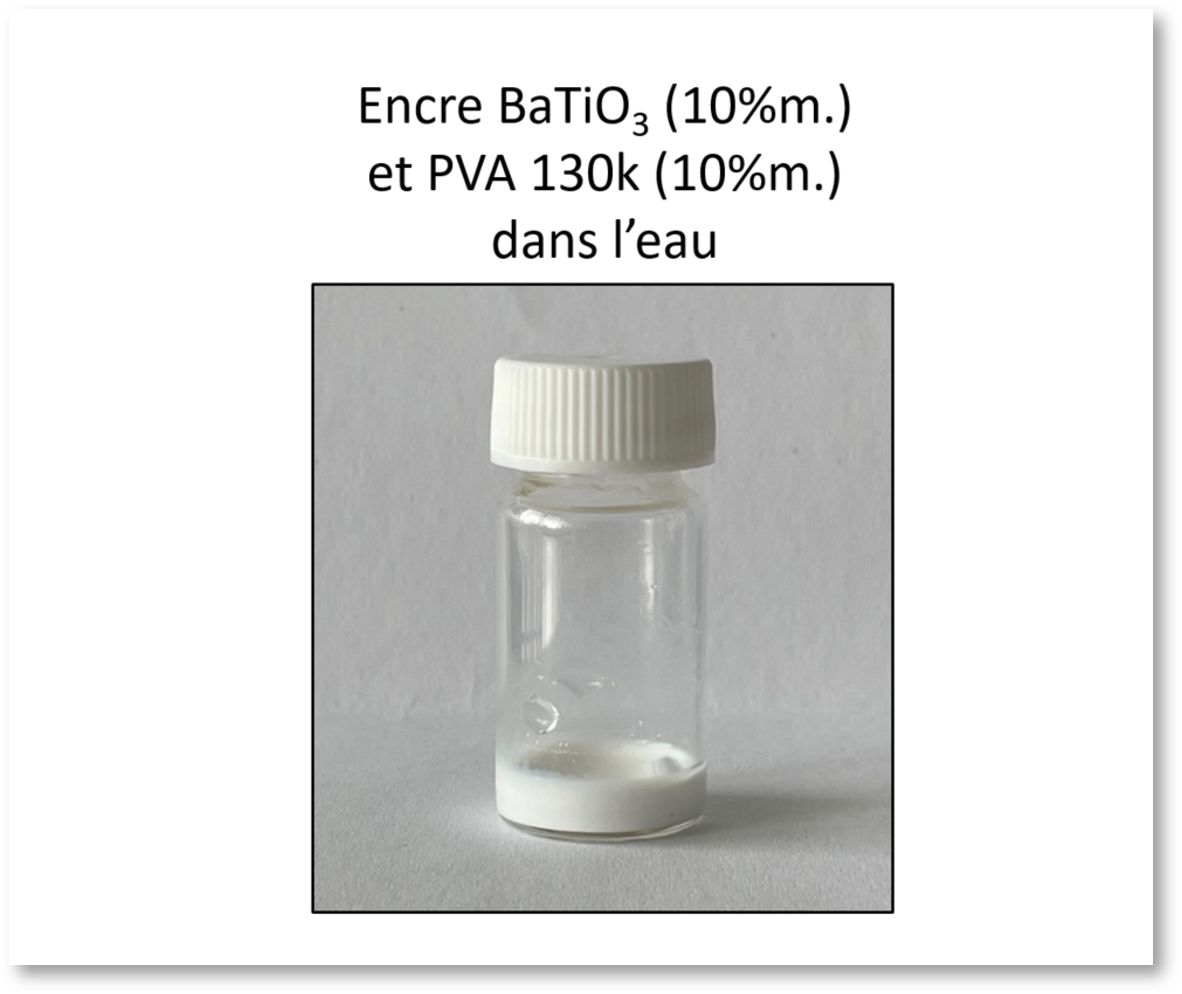

The BaTiO3 nanosheets thus obtained are purified then dispersed in water using polymer additives.

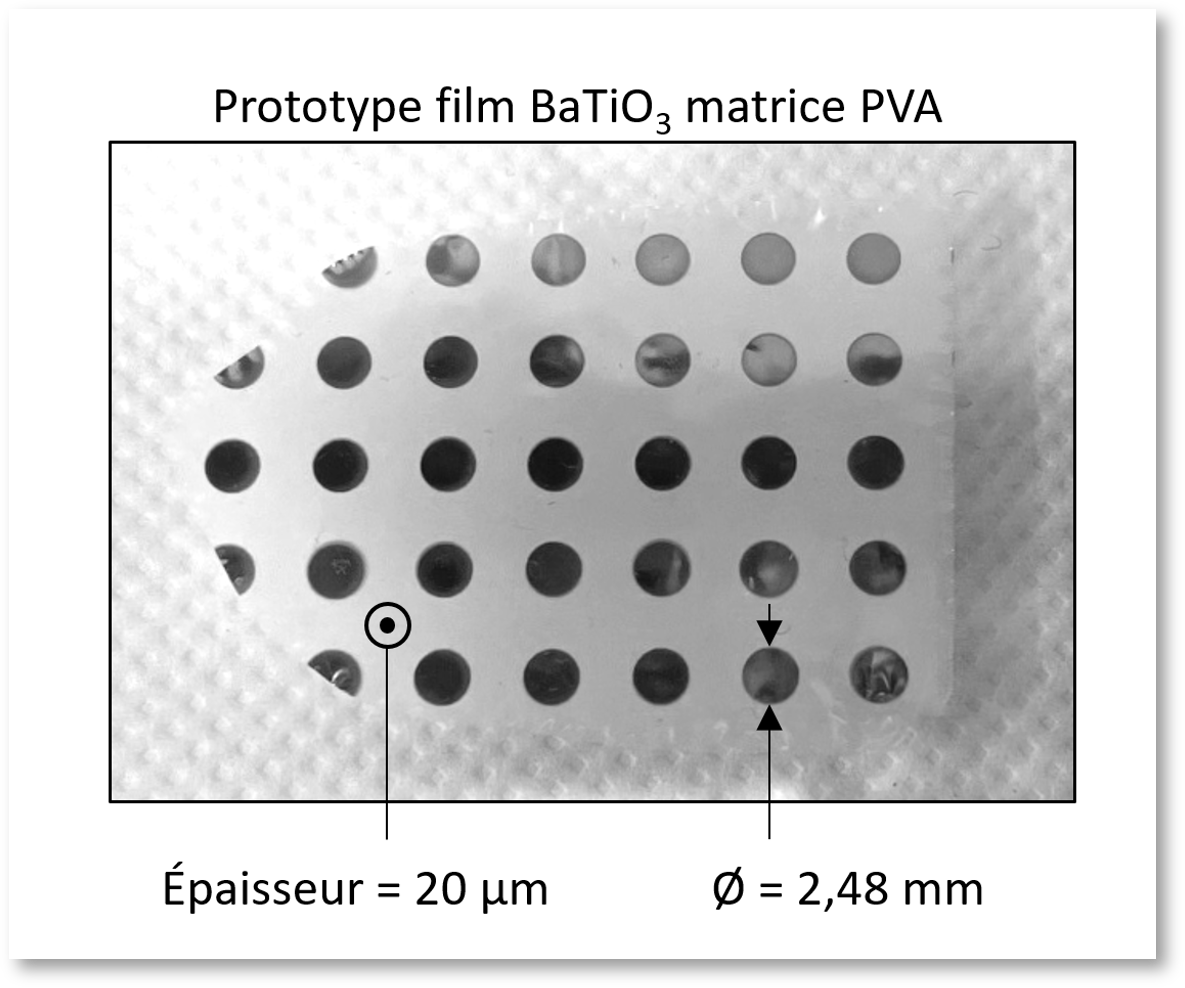

Printing dielectric composite films:

After deposition on a PMMA substrate, dielectric measurements were carried out with the following promising results:

- Real permittivity between 15 and 100

- Losses (Loss Tan) between 0.02 and 0.1

Inventors

Developed by Jinkai Yuan and Maxime Bronchy, CRPP

IP

Patent filed in 2023

PARTNERSHIPS

A company to contribute to maturation and/or obtain an operating license

Contact

Carlos LARRAYA

%63%2e%6c%61%72%72%61%79%61%40%61%73%74%2d%69%6e%6e%6f%76%61%74%69%6f%6e%73%2e%63%6f%6d

+33 (0)5 33 51 43 11